Industrial Pumps Manufacturers

Roto Pumps North America Inc. (RPNA), established in the year 2014, is a 100% subsidiary of Roto Pumps Ltd- a leading industrial pumps manufacturers. RPNA with its own state-of-the-art manufacturing infrastructure in Tulsa, Oklahoma was established with the aim of providing Positive Displacement Pumps, Drop-in-Pumps and Retrofit Parts for the USA market. Also, RPNA has established an extensive network of distributors and channel partners in the USA.

RPNA promotes its range of Progressive Cavity Pumps & Twin Screw Pumps under the brand name of ROTO ULTRA. These pumps are of heavy-duty construction and are designed to pump ‘tough-to-handle’ fluids with ease. Roto’s pumps and spare parts are manufactured under stringent quality standards and strict process control ensuring high performance with a long product life cycle.

Roto Pumps has been helping to move fluids across a range of industries for more than 50 years. We are among the top ten global players of Positive Displacement Pumps manufacturers. We own an integrated, state-of-the-art manufacturing facility to cater to the rising pumping needs of our customers. Our plants are certified by ISO 9001, ISO 14001 and OHSAS 18001. Roto Pumps prides itself in our focused R&D, and strong marketing and sales network spread across five continents. We aim to serve the pumping needs of an optimum number of industries across the globe.

Featured Products

Built on the Maintenance in Place (MIP) Platform, Roto KWIK Pumps have been specially designed and developed to provide easy maintenance with minimum service time while saving on overall maintenance costs.

Performance Summary:

| Capacity | Up to 340 m3 /hr | Viscosity | Up to 30,000 cSt |

| Pressure | Up to 24 bar | High Solid Content | Up to 7% |

Roto Cake Pumps offer a superior solution for handling highly viscous non flowable sludge cake with high dry solid contents up to 45%. Featuring a spacious feed hopper, a separate compression zone, an auger feed screw with enlarged diameter & extended pitch, these pumps are ideal for conveying highly viscous media.

- Capacity – Up to 100 m3/hr (440 GPM)

- Pressure – Up to 24 bar (348 PSI)

The Progressing Cavity Pump is well established as the pump of choice for handling abrasive solids. The wear optimization of the PC pumps is achieved through geometric design for minimum internal fluid velocities and by selecting proper speed & material grade of Rotor & Stator. Wear causes PC pump premature failure as a result of reduction in the volumetric efficiency. Wear compensation stator design allows to control and regulate the efficiency of Progressive Cavity Pumps for an extended period.

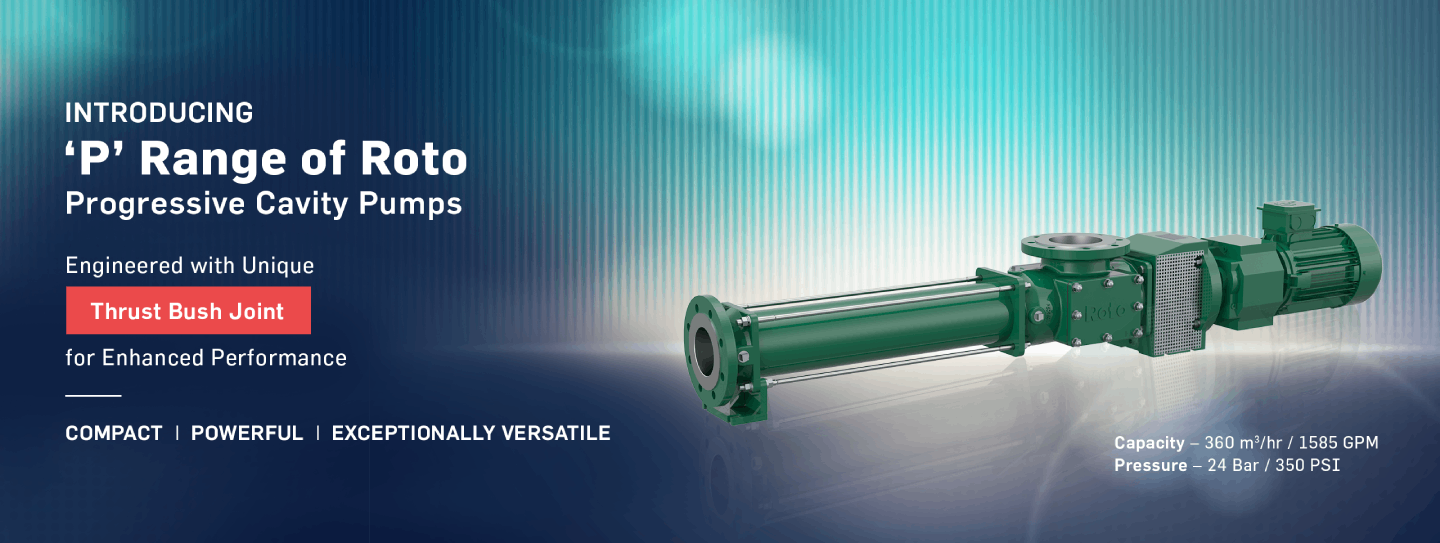

Introducing the new ‘P’ Range Progressive Cavity Pumps, engineered for superior efficiency and reliability in fluid handling. Featuring a unique thrust bush joint, these pumps deliver robust performance, a compact design, and exceptional adaptability across diverse industrial applications.

Flow Rate – Up to 360 m³ /hr / 1585 GPM

Pressure – Up to 24 Bar / 350 PSI

Pump Selector

GLOBAL PRESENCE