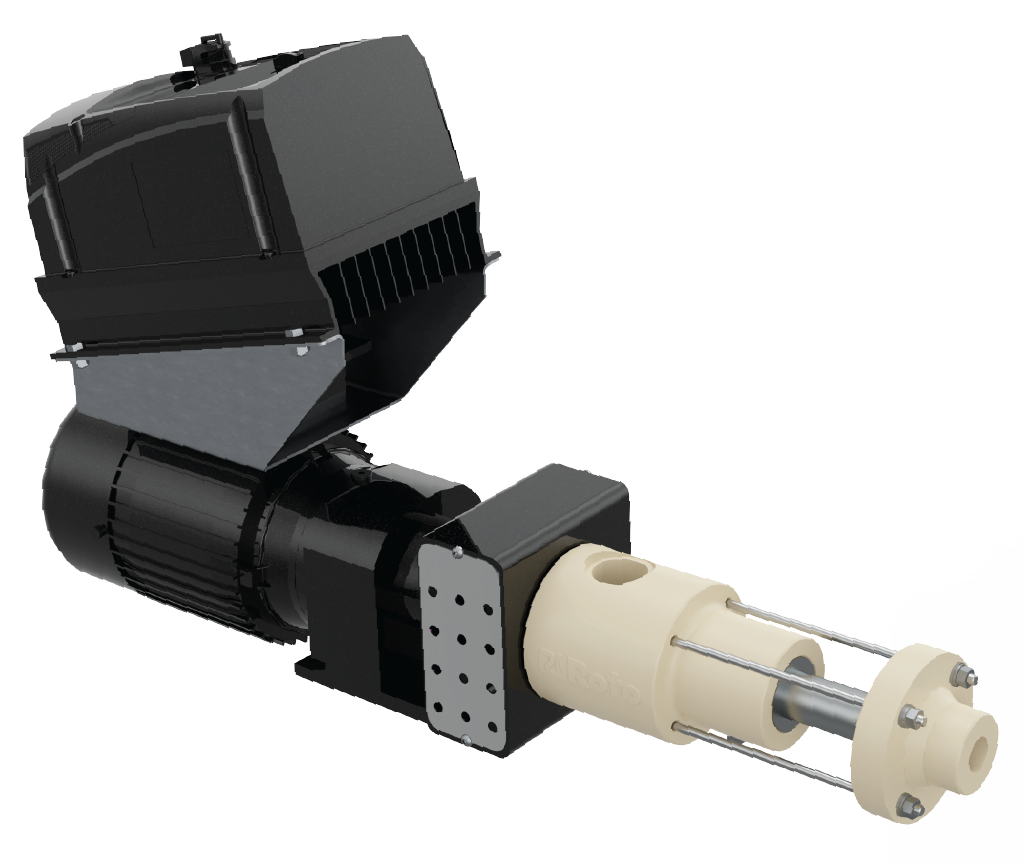

AGGRESSIVE CHEMICAL DOSING PUMP

The Roto Aggressive Chemical (AC) Dosing Pump is our product designed for use with aggressive chemicals. Suitability is achieved by using materials of construction that are resistant to the array of aggressive chemicals found across Industry. Progressive Cavity Pumps of the dosing type have distinct advantages over other pump types commonly used for dosing. The main advantages are a steady flow without pulsation, a high degree of accuracy, the ability to handle entrained solids, suction lift and handling of pressure of up to 24 bar.

Dosing Pump

Flow: 0.17 to 132 GPH / 0.68-500 LPH

Pressure: Up to 350 PSI / 24 bar

DISTINCTIVE FEATURES & BENEFITS

- Capacity is directly proportional to speed.

- High dosing accuracy of +/-1%.

- Low NPSH required & Inherently Self Priming.

- Smooth & Non-Pulsating Flow.

- No need to use Pulsation Dampeners or additional valves.

- No vapour lock & non-clogging

- Easily handles clean and clear liquids to abrasive, corrosive, shear sensitive, viscous and solid laden.

- Easily interchangeability with other models by changing few components.

APPLICATIONS

Strong Acids

• Hydrochloric Acid (HCl)

• Sulfuric Acid (H2SO4)

• Nitric Acid (HNO3)

Strong Bases

• Sodium Hydroxide (NaOH)

• Calcium Hydroxide (Ca(OH)2)

• Ammonium Hydroxide (NH4OH)

Oxidizing Agents

• Sodium Hypochlorite (NaClO)

• Potassium Permanganate (KMnO4)

• Hydrogen Peroxide (H2O2)

Disinfectants

• Sodium Hypochlorite (NaOCl)

• Chlorine Dioxide (ClO2)

• Ozone (O3)

Coagulants and Flocculants

• Aluminium Sulfate (Al2 (SO4) 3)

• Ferric Chloride (FeCl3)

• Polyaluminum Chloride (PAC)

• Polyelectrolytes

Waste Water Applications

• Milk of Lime

• Polymer Solutions

• Metallic Salts

• Polyelectrolyte

• Poly-aluminium Chloride Solution

• Polyacrylamide Solution

• Alum/Polyacrylamide/Concentrated

• Flocculants

Other Applications

• pH Control

• Boiler Water Treatment

• Flocculants

• Disinfection

• Corrosion Inhibitors

• Coagulation (organic and inorganic)

• Cleaning Chemicals

• Oxygen Scavengers

• Organic or Inorganic Contaminate Removal

• Boundary Layer Injection

ROTO ADVANTAGES

1. ROTOR

RJ series rotors are available in stainless steel, AC series rotors are available in Titanium or Hastelloy

material options

2. STATOR

The elatstomeric stator is moulded with integral sealing gasket on both ends effectively prevents corrosion of the stator tube. This design ensures that the pumped media remains isolated, not coming into contact with the stainless steel metal tube or bonding adhesive. The stator elastomers include; Natural, Nitrile, EPDM, Chloro-sulphonated rubber, HNBR, Floroelastomer, and Terfloroelastomer.

3. CONNECTIONS

RJ series is available in Stainless Steel 1″ NPT/DIN Connection at Suction and 1/2” NPT/DIN Connection at Discharge. AC Dosing pump range is availalbe in 1″ NPT

Connection at Suction and 1/2” NPT Connection at Discharge in CPVC or Glass Filled PTFE materials.

4. PUMP HOUSING

Designed for 900 interval rotation for ease in installation. Options available in Stainless Steel / CPVC / Glass Filled PTFE materials.

5. SHAFT SEALING

Standard RJ Dosing pumps are available with Single / Double Mechanical Seal and Gland Packing options. These pumps have seal housing in Stainless Steel. AC Dosing pumps have provision for Plan 62 as standard. These pumps have Seal Housing in Hastelloy as standard .

6. TIE RODS

Four SS316 Tie Rods provides torsional stability & greater resistance to corrosion.

7. PUMP LANTERN

Can accommodate various drives including IEC, NEMA C / Gear Motors. These can be directly flanged to the pump without additional couplings or guards.

8. DRIVE OPTIONS

1. 90V DC Motor – 600 RPM Direct Online.

2. 0.37 kW/0.5 HP Geared Motor.

3. Gearbox and Motor as per NEMA/IEC standard.

4. 0.37 kW/0.5 HP Geared Motor with Integrated VFD to optimize and control the dosing process.

5. Servo Motor.

6. Tophat version in bareshaft option.

9. PLUG IN SHAFT

The pump and drive are designed for effortless disassembly, allowing for rapid replacement of rotating

parts and the shaft seal. Dovel pin ensures a secure shaft-to-drive connection, while the retaining ring

safeguards the bearing against contamination or shaft leakages.